SPINDLE TESTERS

Know when to replace your spindles.

Keeping the Roads Safe

Keeping the Roads Safe

Our serviceable replacement spindles are not our only focus. We care about the safety of you and your families on the road as well as our own family.

We have designed a tool that shop technicians can use to help determine if a spindle has too much wear and could pose a risk for a catastrophic event such as a wheel off accident. These accidents are not only costly, but are potentially deadly.

As a truck and/or a shop owner you have a responsibility to maintain and operate safe equipment on the roadways. If spindle wear is preventing bearings from reaching the proper torque - there is a problem.

Keeping the Roads Safe

Our serviceable replacement spindles are not our only focus. We care about the safety of you and your family on the road as well as our own family.

We have designed a tool that shop technicians can use to help determine if a spindle has too much wear and could pose a risk for a catastrophic event such as a wheel off accident. These accidents are not only costly, but are potentially deadly.

As a truck and/or a shop owner you have a responsibility to maintain and operate safe equipment on the roadways. If spindle wear is preventing bearings from reaching the proper torque - there is a problem.

We see so many people trying to improvise by filing the spindle down so the bearing will slide on. This is not fixing the underlying problem. It will actually cause more damage faster. The spindle must be replaced to bring tolerances back to factory specifications. Otherwise, parts will continue to fail, leak, etc. which will cost more in the long run vs. fixing the problem correctly from the start.

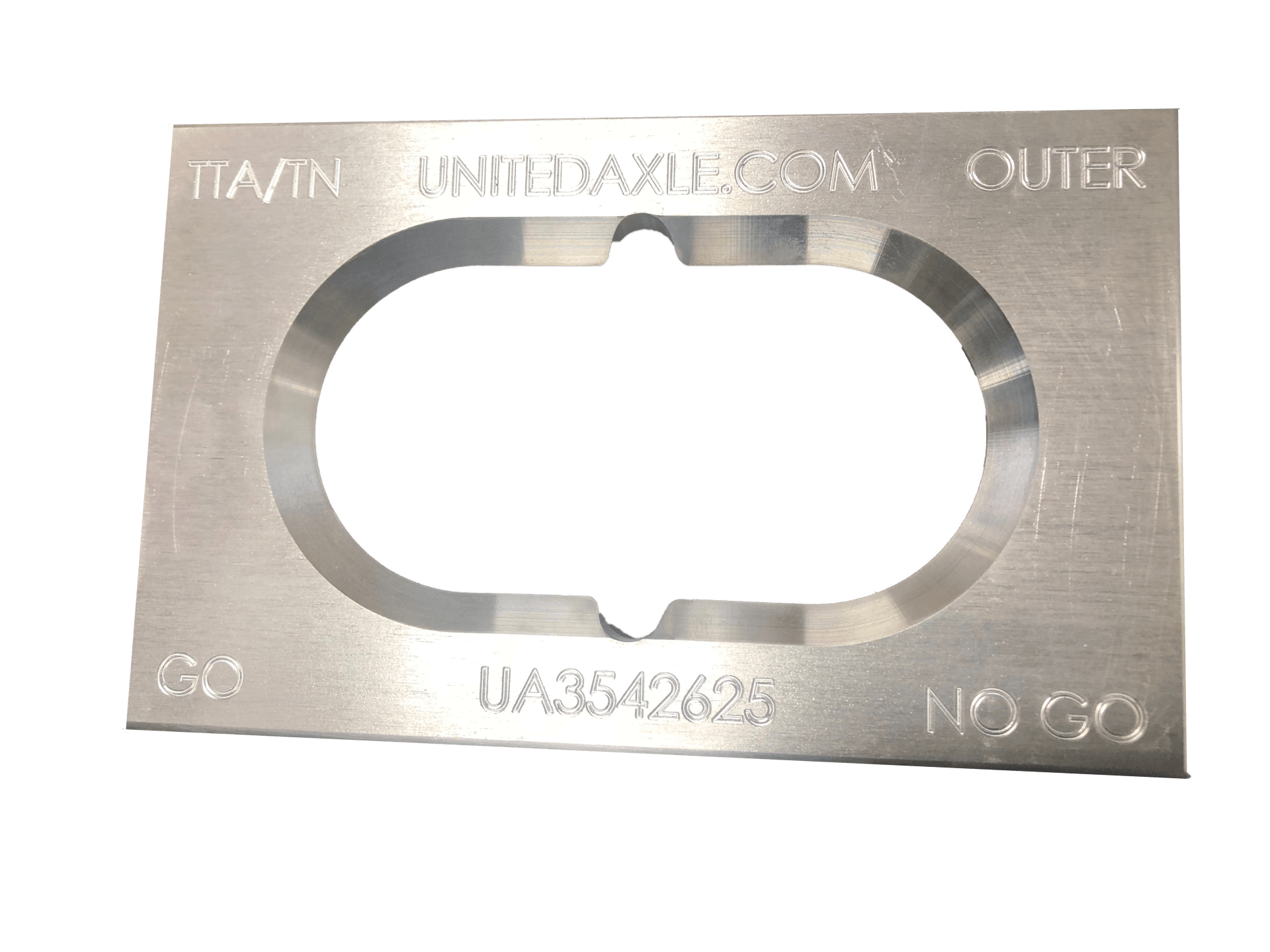

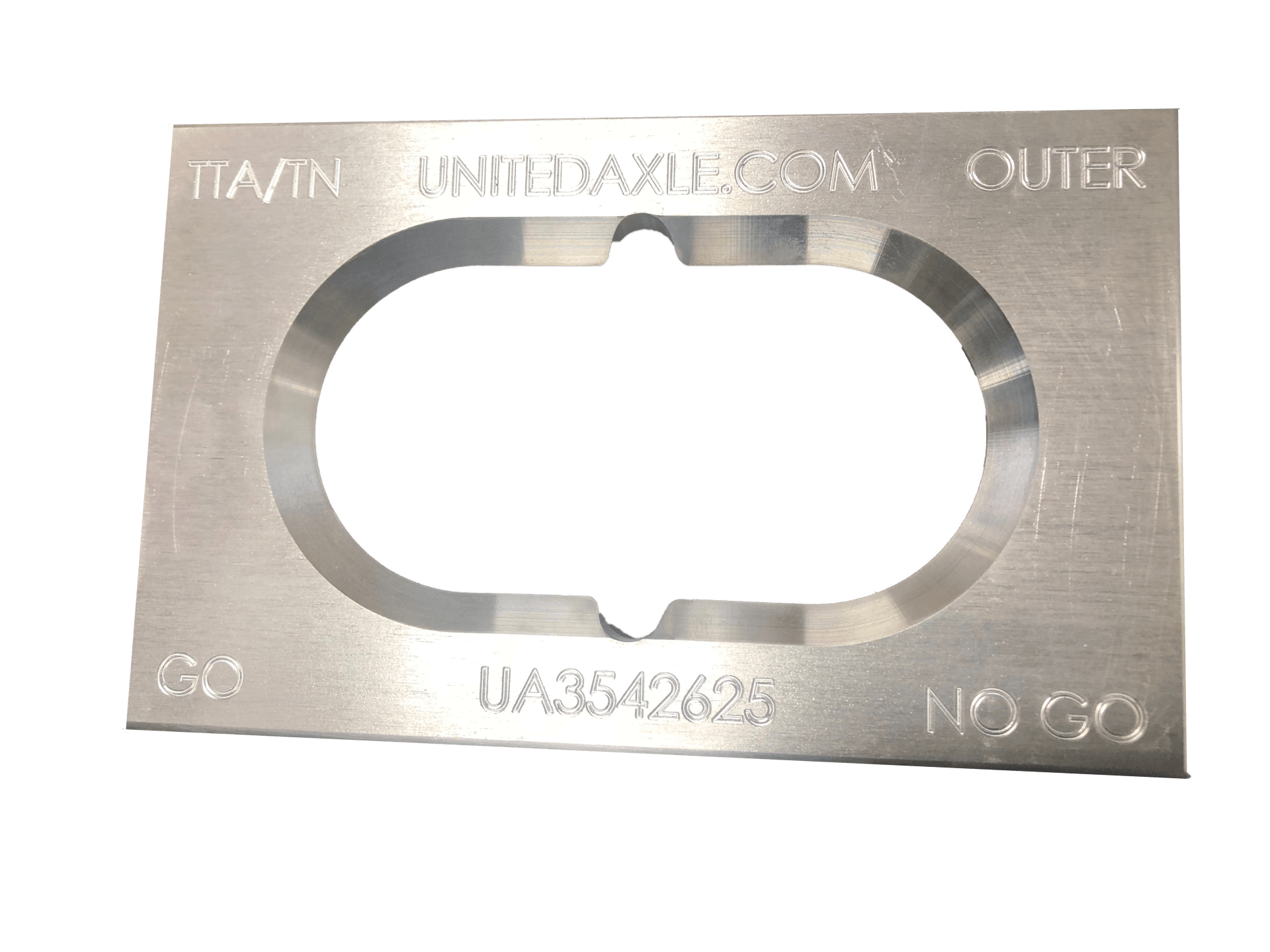

HOW TO USE THE SPINDLE TESTER

The Go-No Go Tool

The tester is slightly larger than the spindle in the center so it can slide onto the spindle end. Once it is slid onto the spindle where the bearing rides, the tool will be used by moving it side-to-side. On one side of the tool you will see the word "GO" and the other side of the tool are the words "NO-GO" which indicates there is too much wear on the spindle between the bearing race and the bearing journal.

The design of the tool was meant to make it easy for the user. The aluminum material makes the tool lightweight and maintains tight tolerances for checking spindles if stored properly.

The spindle should be checked side-to-side and then turned in a clockwise direction around the spindle to check all directions for spindle wear. Most of the time the wear will be found on the underside of the spindle. If at any time the tool moves to the "NO-GO" side when attempting to slide the tool back and forth around the bearing journal area - THE SPINDLE SHOULD BE FLAGGED AND REPLACED.

HOW TO USE THE SPINDLE TESTER

The Go-No Go Tool

The tester is slightly larger than the spindle in the center so it can slide onto the spindle end. Once it is slid onto the spindle where the bearing rides, the tool will be used by moving it side-to-side. On one side of the tool you will see the word "GO" and on the other side of the tool are the words "NO-GO" which indicates there is too much wear on the bearing journal.

The design of the tool was meant to make it easy for the user. The aluminum material makes the tool lightweight and maintains tight tolerances for checking spindles if stored properly.

The spindle should be checked side-to-side and then turned in a clockwise direction around the spindle to check all directions for spindle wear. Generally, the wear will be found on the underside of the spindle. If at any time the tool moves to the "NO-GO" side when attempting to slide the tool back and forth around the bearing journal area - THE SPINDLE SHOULD BE FLAGGED AND REPLACED.

Certified & Guaranteed:

10-day money back guarantee less shipping costs. Buyer is responsible for return shipping fees. Tester gages are inspected and tested in a climate controlled facility to ensure accuracy prior to shipping. Tester gages should not be stored in extreme temperatures and should be kept between 65-85 degrees to maintain accuracy for measurement.