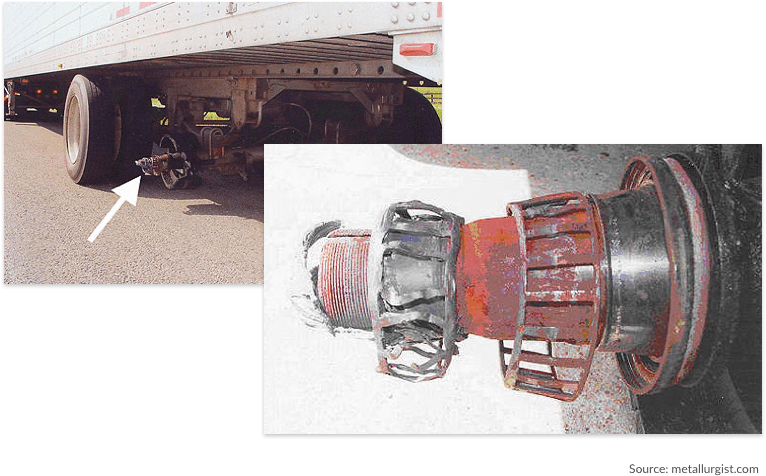

Don’t let this happen to you!

Did you know it's estimated over 52K wheel offs every year in the United States???

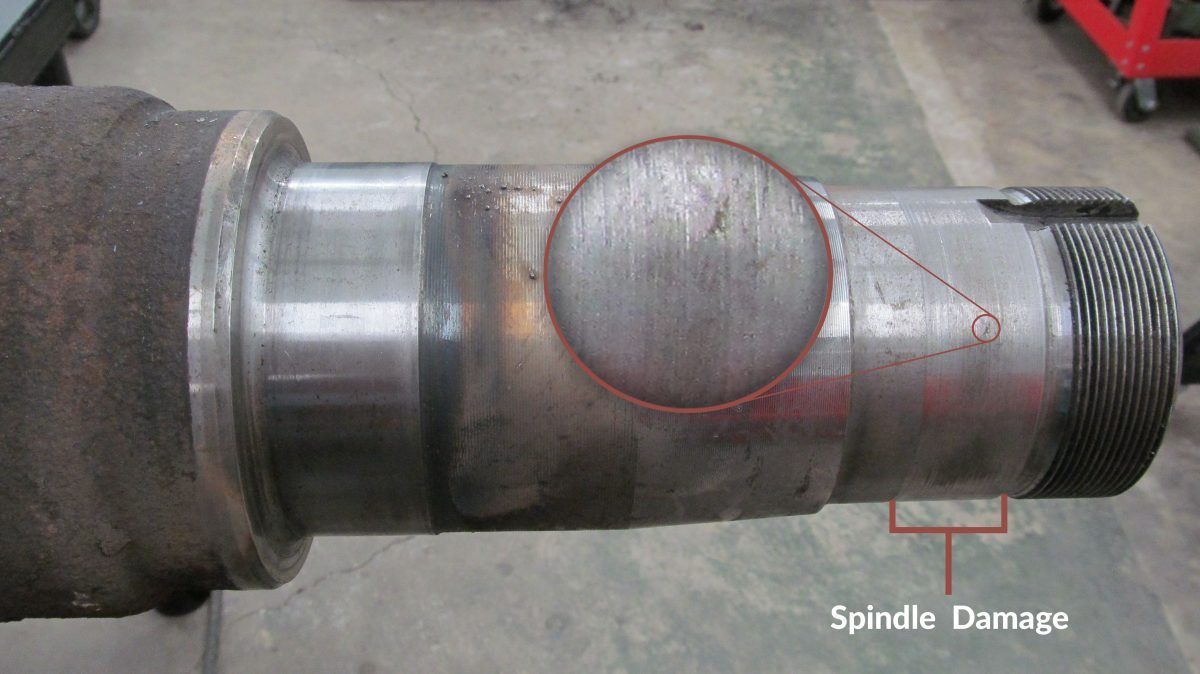

When you take your truck into the shop for maintenance and repairs, are you aware of what could be hiding inside your hubs? – A DAMAGED SPINDLE. Spindle axles should be inspected for wear, fatigue, cracks or obvious damage because they are a wear item that will need replaced over time.

Spindle damage can be caused by a variety of factors which can include but not limited to: high mileage, bearing failure, improper bearing installation.

More than half the vehicles with over 600,000 miles and all vehicles with over 1,000,000 miles will have cyclical wear pattern on the bearing journal areas where the bearings and the spindle surface have been rubbing over a period of time.

Avoid Catastrophic Failure

In 2016 there were 138,401 trucks nationwide found by inspection stations with oil grease leaks

Are you educating your maintenance technicians about spindle damage? Spindle inspection should be a mandatory item on your preventative maintenance checklist. Not replacing damaged spindles could be a detrimental liability if a vehicle loses a wheel on the highway. Spindle damage can cause too much play on the bearing journals. If repeated bearing or seal replacements are needed then, it could possibly be a spindle that needs to be replaced to bring the axle end back to factory specifications for proper fit. If the underlying problem – A DAMAGED SPINDLE is not replaced, the continuous problematic wear adds to the fretting corrosion on the spindle which could eventually lead to a catastrophic event.

Source: www.fmcsa.dot.gov

Spindle Damage Can Be Overlooked

If you see spindle damage when performing work AND you say nothing to the vehicle owner you are putting yourself and your shop in a vulnerable position. Would you ever reinstall bad brakes because the owner couldn’t afford to fix it – ABSOLUTELY NOT! It would create an unsafe situation for everyone on the road and it would make you liable in the event of an accident. The same is true for damaged spindles. The vehicle owner should be notified if spindle damage is found. Occasionally spindle damage will be obvious, but many times it is NOT. You will need a micrometer to measure the spindle. A spindle measured under 0.006” of its standard size is deemed bad. Protect your business and make the call!