Our Process

Our Process starts with a phone call from the repair shop or truck owner in need of a new spindle.

A UA certified spindle technician will arrive on location in their fully equipped mobile service vehicle. The technician will begin by removing the spindle. Once the damaged spindle is removed, the axle tube will be machined. Threads will be integrated into the axle tube.

At this point, the axle is transformed with an end that can be serviced over and over!

A new spindle is threaded into place and torqued down. Then, a final weld is made. The initial installation takes only three hours to complete from start to finish.

If the spindle is ever in need of replacement again it can be easily removed. Our Spindle Specialist will cut the weld and remove the old spindle. Then, a new spindle can be threaded back into place. This replacement process is completed in under two hours .

.01

The majority of roadside breakdowns are tire related. Properly identifying bad spindles can help prevent you from becoming part of this statistic. Red flags to watch out for include: metal shavings in hub oil, wheel seal leaking, or hub hot to the touch after driving distances. Running a truck on bad bearings increases the chance of damaging the spindle. Once damage has occurred options are limited. Either entire axle will need replaced or spindle replacement. United Axle has revolutionized the replacement spindles and process.

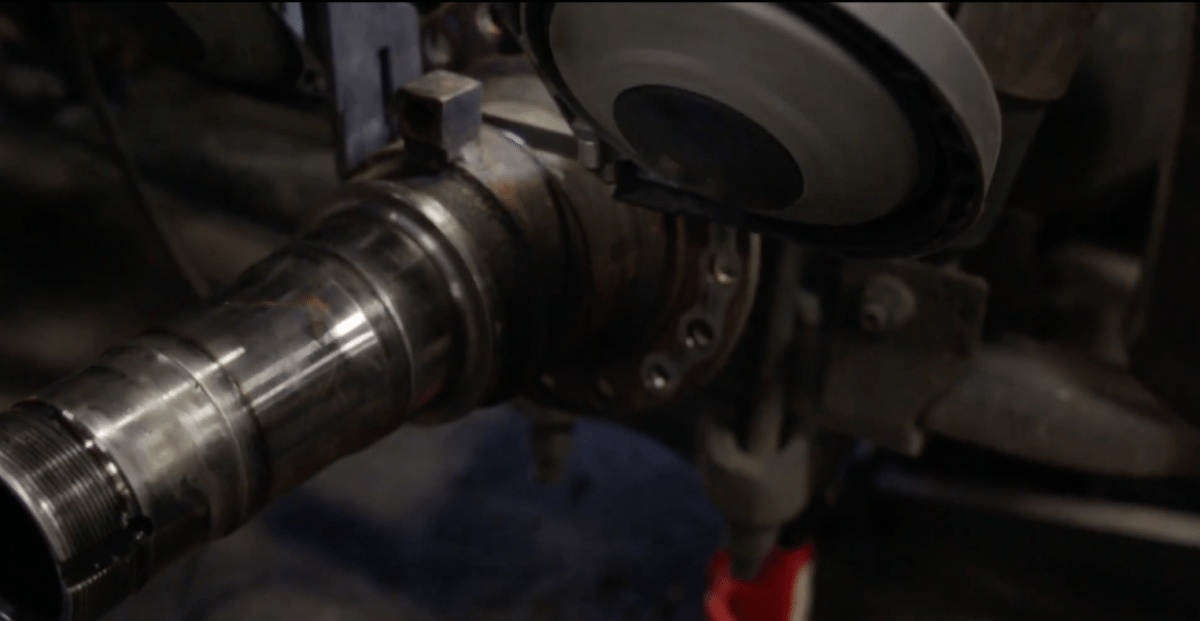

The first step in the replacement process is the remove the old damaged spindle. We can then smooth and clean up the axle tube in preparation for the new threaded spindle.

.02

Thread

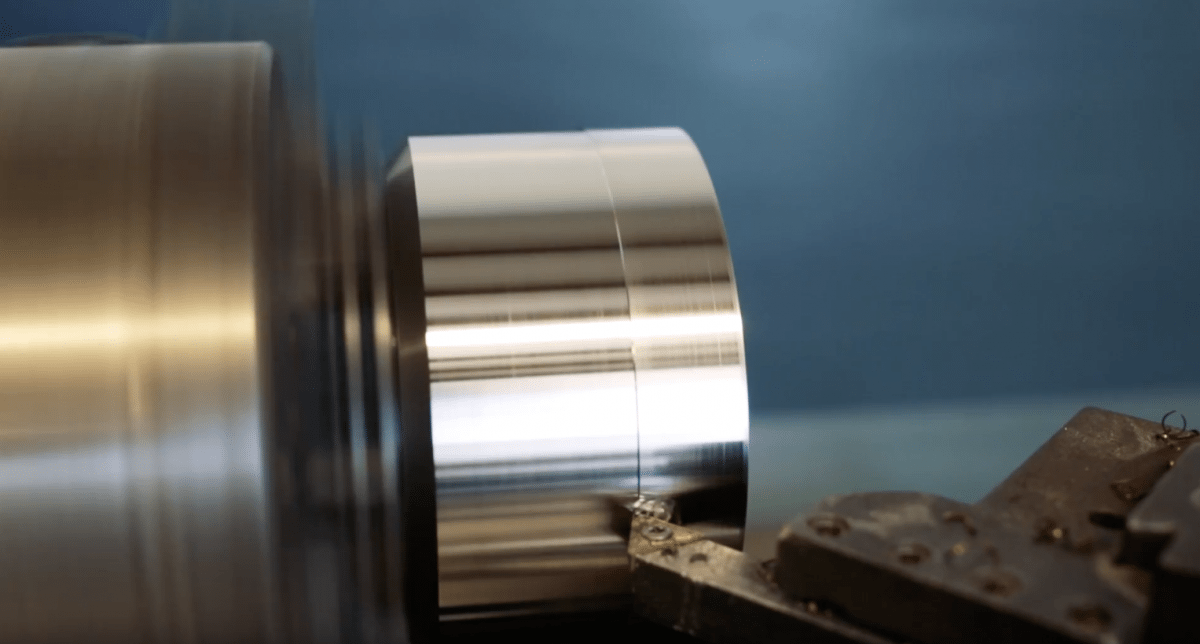

After axle tube is prepared, the bushing is machined to custom fit the axle tube. Once the precise size has been achieved, the axle tube can now be threaded to accept the new spindle replacement. It is then threaded into the axle tube and torqued down to specifications.

.03

Install

Once the spindle is threaded in and torqued down, our technician can make the final weld. This will seal the axle housing for drives and air suppression systems.

Once our spindle technician has completed the spindle replacement, the vehicle is ready for wheel assembly.

Product &

Installation Warranty

We are committed to customer satisfaction and providing a professional quality axle repair, therefore a limited 3-year Warranty is provided to the original owner of the repair on parts and 90-day on labor. Warranty will not cover damage caused by lack of maintenance or damage due to bearing failure or damage caused by abuse, misuse, neglect, accident, or overloading. The sole remedy for breach of any warranty against United Axle is limited to the money actually received by United Axle for the part and/or labor. United Axle will not pay outside labor.

Warranty Policy recently updated (2022)

Click below to view detailed warranty information.